Inventory of Innovative Indoor Smoke

Alleviating Technologies in Nepal

41

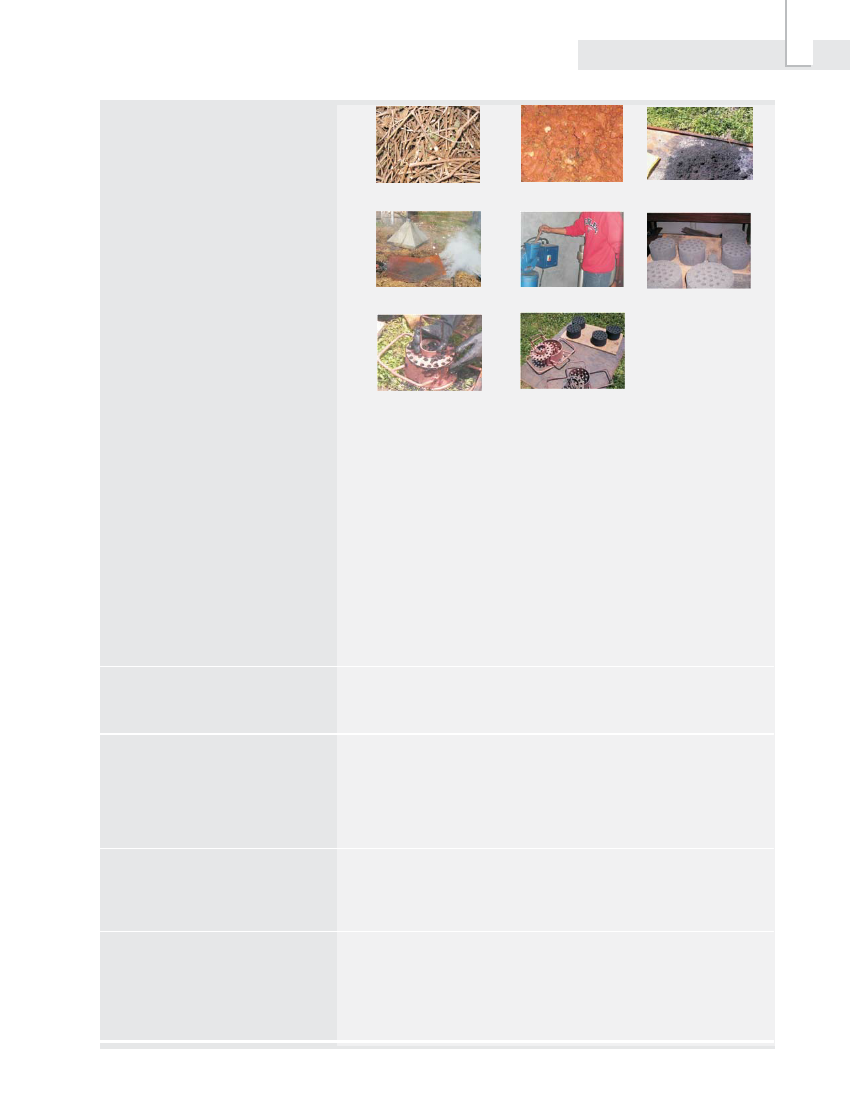

Sun dried banmara

Benthonite Clay

Preparing mixture

Charring banmara

Grinding charcoal Dried briquettes

Disseminated regions

Advantages

Disadvantages

Major organisations involved in

promotion/dissemination

Briquetting mould

Preparing briquette

Photograph 4.3: Materials and production of beehive briquette

Source: RONAST

Water is added to the mixture to form a paste which is then filled in

a mould of different sizes. After pressing the paste in the mould

manually, the paste is removed from the mould and dried under the

sun for five days. It is difficult to maintain consistence in weight as

the compaction is done manually. The materials and procedure

required for producing beehive briquette is shown in Photograph 4.3.

The cylindrical type briquettes are common with a height of 5.5 inches

in diameter. There are 19 evenly distributed holes of 1 cm diameter

along the direction parallel to the cylindrical axis, which facilitates

proper supply of air for better combustion. It weighs 0.5 kg and its

color varies from gray to black. It burns for 60 to 90 minutes.

Bishankhunarayan of Lalitpur; Nawadurga and Kamdi of Banke;

Marsangidhi and Turture of Tanahu; and Panchpokhari and Shantinagar

of Jhapa. Suitable in all areas where raw material is easily available.

Easy to handle, transport and store as an alternative environment

friendly fuel and less polluting. Furthermore, it has a good business

potential because of low investment requirement. Suitable for slow

heating (simmering) and cooking, space heating and more applicable

in barbecue preparation. Suitable for all geographic and climatic

condition.

The production is stopped during monsoon since raw materials need

to be completely dry before charring. Lack of adequate funding for

capital investment and training are the barriers to implement this

technology at a large scale.

IDS-N, NAST and RECAST.